In Saudi Arabia’s industrial sector, HVAC (Heating, Ventilation, and Air Conditioning) systems are critical for maintaining safe, comfortable, and efficient environments — especially in the country’s extreme climate conditions. Whether it’s a food processing plant or a high-tech manufacturing facility, Variable Frequency Drives (VFDs) can transform how HVAC systems operate, delivering cost savings and performance improvements.

Why HVAC Systems Matter in Saudi Industries:

- High Cooling Demand: Saudi factories run year-round in hot weather conditions, making efficient HVAC systems essential.

- Energy Costs: HVAC systems consume a significant portion of total electrical energy in industrial and commercial facilities.

- Process Sensitivity: In sectors like pharmaceuticals and electronics, temperature and air quality control directly affect product quality.

How VFDs Optimize HVAC Systems:

- Energy Efficiency Gains:

Traditional HVAC motors run at a constant speed regardless of demand. VFDs adjust the motor speed based on real-time load, ensuring the system only consumes as much energy as needed. - Precise Temperature Control:

VFD-driven fans and pumps can modulate air and water flow rates, maintaining stable temperatures and humidity levels critical for sensitive manufacturing processes. - Extended Equipment Life:

By soft-starting motors and reducing sudden load changes, VFDs minimize wear and tear, increasing HVAC system longevity. - Reduced Maintenance Needs:

Less mechanical stress means fewer component failures, resulting in lower repair costs and system downtime. - Lower Operational Costs:

Case studies show that implementing VFDs in HVAC systems can reduce energy bills by up to 40%, leading to rapid return on investment (ROI).

Real-World Example:

A major food processing facility in Jeddah installed VFDs on its chilled water pumps and air handling units (AHUs). The results included:

- 30% reduction in energy consumption.

- Improved temperature stability in production zones.

- Maintenance cost savings of 20% annually.

How VFDs Optimize HVAC Systems:

- Energy Efficiency Gains:

Traditional HVAC motors run at a constant speed regardless of demand. VFDs adjust the motor speed based on real-time load, ensuring the system only consumes as much energy as needed. - Precise Temperature Control:

VFD-driven fans and pumps can modulate air and water flow rates, maintaining stable temperatures and humidity levels critical for sensitive manufacturing processes. - Extended Equipment Life:

By soft-starting motors and reducing sudden load changes, VFDs minimize wear and tear, increasing HVAC system longevity. - Reduced Maintenance Needs:

Less mechanical stress means fewer component failures, resulting in lower repair costs and system downtime. - Lower Operational Costs:

Case studies show that implementing VFDs in HVAC systems can reduce energy bills by up to 40%, leading to rapid return on investment (ROI).

Real-World Example:

A major food processing facility in Jeddah installed VFDs on its chilled water pumps and air handling units (AHUs). The results included:

- 30% reduction in energy consumption.

- Improved temperature stability in production zones.

- Maintenance cost savings of 20% annually.

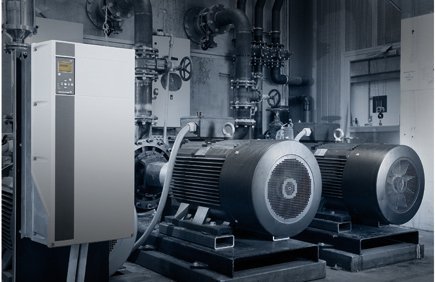

Where VFDs Are Applied in HVAC Systems:

- Chillers: Optimize compressor speeds for cooling efficiency.

- Pumps: Adjust chilled and hot water flow to meet cooling/heating loads.

- Fans and Blowers: Control air movement in AHUs and exhaust systems.

- Cooling Towers: Modulate fan speeds for heat rejection.

Considerations for VFD Use in Saudi Arabia:

- High Ambient Temperatures:

Ensure VFDs are rated for high-heat environments common in outdoor installations. - Harmonics Mitigation:

Use filters or line reactors if sensitive electronic equipment is nearby. - System Integration:

VFDs should be integrated with Building Management Systems (BMS) or SCADA for centralized control. - Local Support:

Work with suppliers like Tesla East for expert installation, configuration, and maintenance support.

Government Energy Programs:

Saudi Arabia’s Vision 2030 initiative encourages industrial energy efficiency. Factories adopting VFD-driven HVAC systems may qualify for energy-saving incentives or certifications.

Conclusion:

Incorporating VFD technology into HVAC systems is no longer optional for Saudi industries aiming for cost reduction, process reliability, and energy sustainability. It’s a proven, scalable solution offering both immediate and long-term benefits.