In recent years, the demand for energy-efficient solutions in Saudi Arabia’s industrial sector has grown significantly. As factories and processing plants aim to reduce operational costs and meet environmental standards, Variable Frequency Drives (VFDs) have emerged as a key technology in industrial automation and energy management.

What is a VFD?

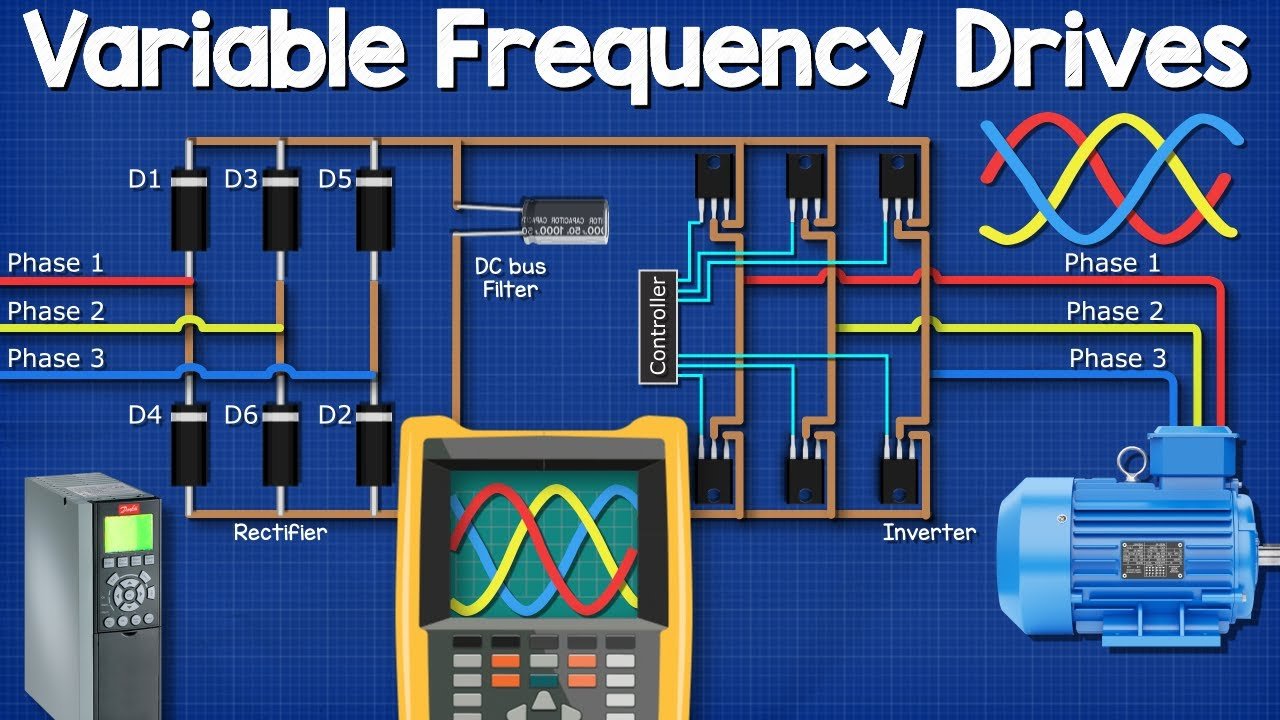

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of electric motors by varying the input frequency and voltage. This precise control allows equipment such as pumps, fans, and conveyors to operate at optimal speeds rather than running at full capacity continuously.

Why VFDs are Essential in Saudi Arabia’s Industry:

Saudi Arabia’s industrial operations—spanning oil & gas, petrochemicals, food processing, and water treatment—rely heavily on electric motors. Using VFDs can dramatically cut down electricity consumption, which translates into:

- Lower utility bills.

- Less mechanical stress on equipment.

- Improved system performance.

Top Benefits of VFDs in Industrial Applications:

- Significant Energy Savings:

By adjusting motor speeds to match actual demand, VFDs can reduce energy consumption by up to 50% compared to fixed-speed systems. - Extended Equipment Life:

Gradual motor starts and stops minimize wear and tear, increasing the lifespan of motors, pumps, and other connected devices. - Reduced Maintenance Costs:

With less mechanical stress, components require less frequent maintenance, lowering overall downtime. - Process Optimization:

VFDs enable fine-tuned control over production processes, ensuring greater consistency and product quality. - Improved System Reliability:

VFDs can detect and respond to system irregularities, preventing potential damage and production halts.

Where VFDs are Used in Saudi Industries:

- Oil & Gas: Pumping systems, compressors, drilling rigs.

- Water Treatment: Pumping stations, aerators, filtration systems.

- HVAC Systems: Fans, blowers, and air handling units in commercial and industrial facilities.

- Food & Beverage: Mixers, conveyors, packaging equipment.

Energy Cost Example:

A Saudi-based manufacturing plant using a VFD on its main pump system reported:

- Energy savings: 30% reduction in power consumption.

- Payback period: Less than 12 months.

- Maintenance reduction: 25% drop in service calls related to motor failure.

Government Incentives for Energy Efficiency:

As part of Vision 2030, the Saudi government promotes energy efficiency in the industrial sector through initiatives and incentives. Investing in VFD technology not only improves operational performance but may also qualify businesses for energy-saving grants or rebates.

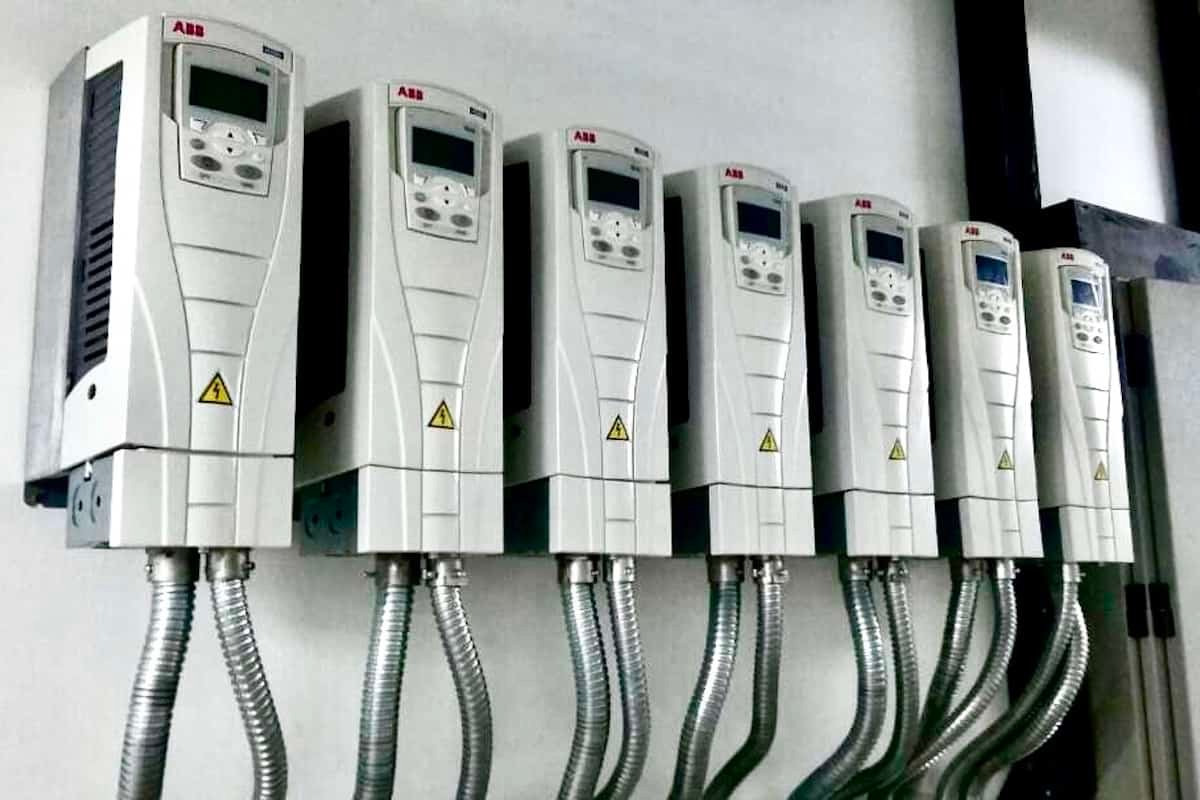

VFD Selection Tips for Your Factory:

- Motor Compatibility: Ensure the VFD matches the motor type (induction, synchronous, etc.).

- Load Type: Consider whether the application is constant or variable torque.

- Environmental Conditions: Select VFDs rated for temperature, humidity, and dust conditions common in Saudi factories.

- Control Features: Advanced VFDs offer additional features like harmonic filtering and remote monitoring (can integrate with SCADA systems).

Conclusion:

Upgrading to VFD technology is a smart investment for any industrial facility in Saudi Arabia looking to reduce energy costs, enhance process control, and extend equipment lifespan. Whether it’s for pumps, fans, or complex machinery, VFDs deliver measurable benefits that directly impact your bottom line.