As industrial operations in Saudi Arabia become more complex and competitive, the need for efficient monitoring and control systems is greater than ever. This is where SCADA systems (Supervisory Control and Data Acquisition) come into play, offering factories and plants real-time control over processes, energy use, and productivity.

What is a SCADA System?

A SCADA system is an industrial control system used to monitor and manage production, equipment, and plant operations from a centralized location. It gathers data from various sensors and devices across the facility, processes the information, and allows operators to make informed decisions instantly.

Key Features of SCADA Systems:

- Real-Time Monitoring: Track process performance, equipment status, and production data.

- Data Logging & Reporting: Collect historical data for analysis and optimization.

- Alarm Management: Automatically detect and notify operators of faults or irregularities.

- Remote Control: Operators can adjust system parameters remotely via HMI (Human Machine Interface).

Benefits of SCADA Systems for Saudi Factories:

- Improved Process Efficiency:

By continuously monitoring system performance, SCADA enables early detection of inefficiencies or malfunctions, leading to smoother and faster operations. - Reduced Downtime:

Alarms and alerts prevent costly equipment failures by notifying staff before issues escalate. - Energy Management:

SCADA tracks energy consumption in real-time, helping factories implement energy-saving strategies and reduce electricity bills. - Better Quality Control:

Consistent monitoring ensures product quality remains high by maintaining optimal process conditions. - Enhanced Safety:

Critical parameters such as temperature, pressure, or chemical levels can be tracked to prevent dangerous situations.

SCADA Applications in Key Saudi Industries:

- Oil & Gas: Pipeline monitoring, refinery process control, storage tank management.

- Water & Wastewater: Pump station control, water treatment, distribution system management.

- Manufacturing: Assembly line supervision, machine performance tracking.

- Energy: Power plant management, renewable energy monitoring (solar, wind).

SCADA and Industry 4.0 in Saudi Arabia:

As the Kingdom moves towards Industry 4.0, SCADA plays a crucial role by integrating with IoT devices, cloud platforms, and advanced analytics. This transforms traditional factories into smart facilities capable of self-optimization and predictive maintenance.

Challenges to Consider:

- Cybersecurity Risks:

SCADA systems are potential targets for cyber attacks. Implementing secure networks and regular updates is essential. - Integration Complexity:

SCADA must integrate with existing PLCs, HMIs, and VFDs for full effectiveness — proper system design is crucial.

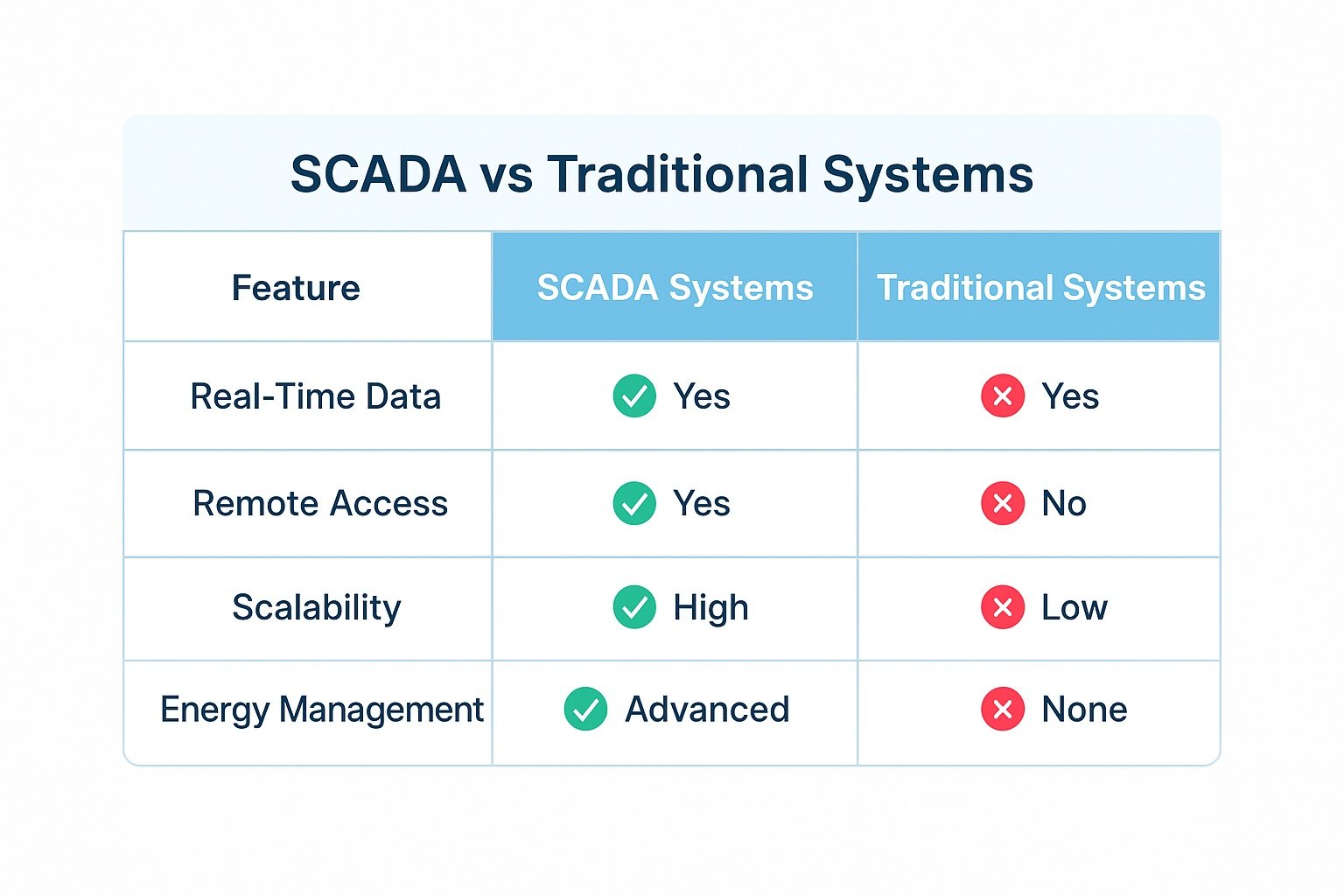

SCADA vs. Traditional Control Systems:

Conclusion:

For Saudi industries, investing in SCADA is not just a trend — it’s a necessity to remain globally competitive. SCADA systems ensure optimized processes, reduced costs, and better decision-making, especially as industrial plants scale operations under Saudi Vision 2030.